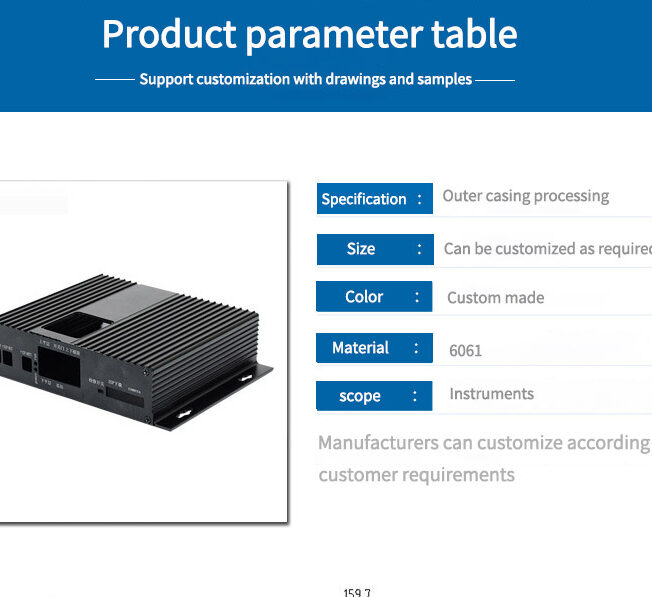

Production process and technology

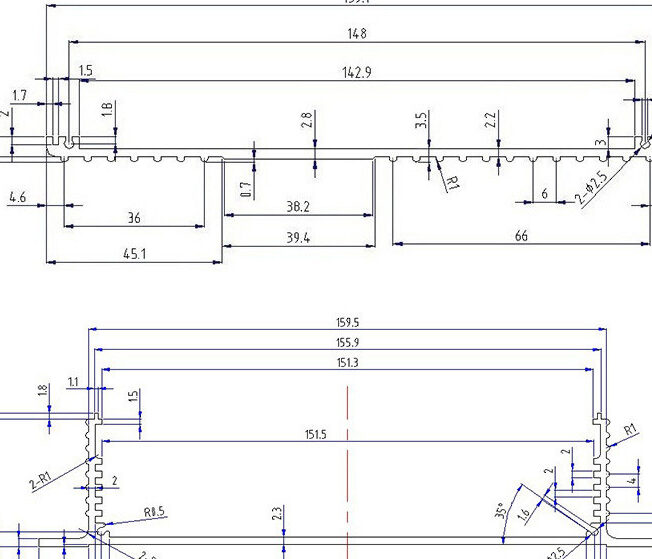

The manufacturing processes of aluminum alloy shells mainly include extrusion, rolling, casting, etc. These processes directly affect the performance and price of the product. For example, the aluminum alloy shell produced by the extrusion process has high strength and stiffness, but the production cost is also relatively high. The casting process is more suitable for the production of large aluminum alloy casings, but there may be certain pores and shrinkage cavities.

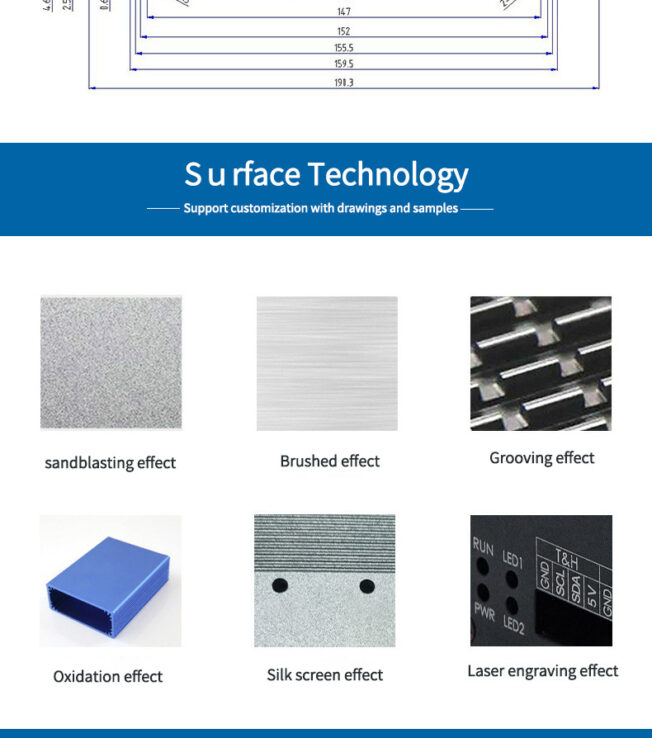

Surface treatment and coating methods

There are many surface treatment methods for aluminum alloy shells, such as spraying, electroplating, anodizing, etc. These treatments can improve the aesthetics, enhance corrosion resistance, and protect internal electronic components from the external environment. For example, anodizing can produce a dense oxide film to improve the corrosion resistance and wear resistance of aluminum alloys. Common coating cases include spraying insulating paint, anodizing dyeing, etc.